Overview

The system is modular, running on an RS485 (industrial) network. Modules are powered over the network cabling. The software design is our own, as are the custom printed circuit boards. Initial versions use as many pre-built sub-modules mounted to these as possible to keep fabrication costs down.

- No collector to tank heat exchanger.

- No glycol, 15% higher efficiency, 30% longer life.

- No heat dump, no boiling problems.

- No freeze problems.

- No pressure vessels, system shuts down at 70C.

- Almost maintenance free, durable. Just maintain water level!

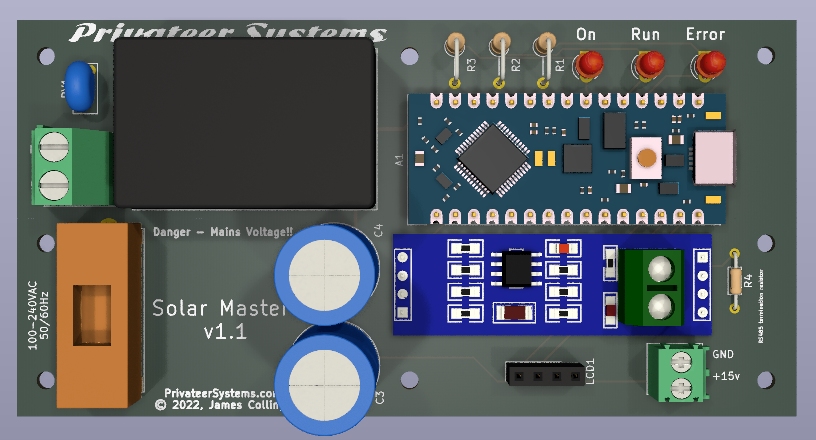

Master control unit

The master unit is the main control module for the Privateer Systems drainback solar system. It controls:

- 4x solar collector arrays, each with multiple collectors

- 4x variable speed pumps

- 4x separate accumulation tanks, typically each 1,000 litres+

- Logging information

- Controls the RS485 network

The master unit reads data from the roof-top (remote) temperature units, pump units, and tank digital temperature sensor units. Based on this data, the system will constantly vary the pump speed/s to chase the best efficiency it can for each collector bank.

If your collector banks are oriented differently, different pumps will run at different flow rates as the sun strikes the banks differently. If your system requires different temperature water in different tanks, different banks can produce that.

If the collector bank’s temperature reduces to approach that of the tank (eg. cloud, incident angle, daylight), the flow will decrease to try to obtain at least the permitted temperature delta from the bank to tank. Eventually, it will stop and hold, and then, if the sun has been absent for a while, will allow complete drain-back from the collector bank to the tank.

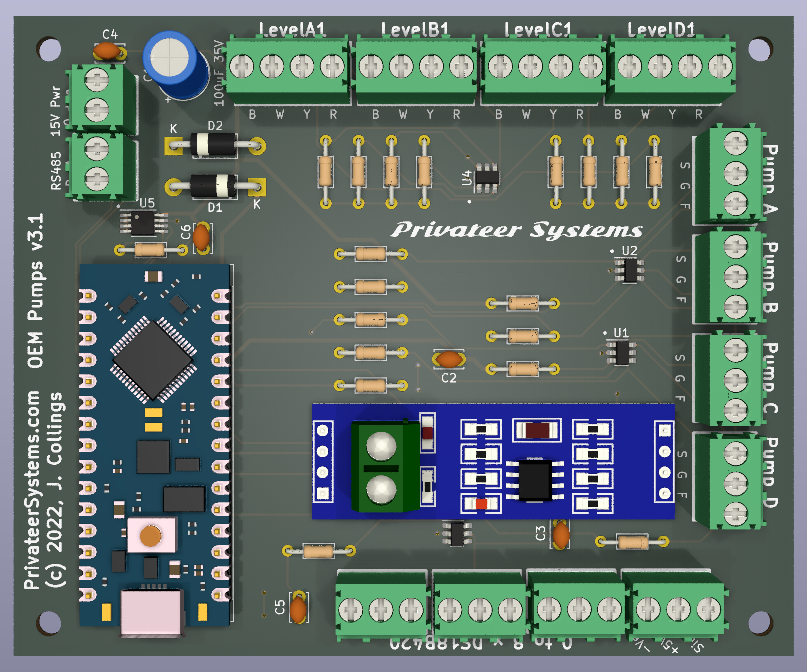

Pumps

The OEM pumps we use allow us to vary their speed dynamically and they transmit the fluid flow rate back in real-time. Pump data is read and written by our proprietary pump module/s. They connect to the master unit over the RS485 network. The master unit thereby intelligently controls the pump/s.

The OEM pumps we use allow us to vary their speed dynamically and they transmit the fluid flow rate back in real-time. Pump data is read and written by our proprietary pump module/s. They connect to the master unit over the RS485 network. The master unit thereby intelligently controls the pump/s.

We have solved various fluid to gas transition problems and can run our system in a semi-syphon mode, thereby reducing pump power requirements.

Variable speed pumping allows optimum efficiency, both in the collection of solar energy, and in the energy used to run the pump/s. We typically see a coefficient of performance of 70:1 between the two.

Collectors

We use custom made ‘all-copper’ flat plate collectors. The manifolds, risers and fins are copper. This is to eliminate possible galvanic corrosion occurring between aluminium fins which are often welded to copper pipes in other collectors. This all copper design gives better thermal efficiency and has a long life.

We recommend collector banks to be no more than four collectors wide because of thermal expansion. Banks can be laid out so that one bank is above the other on the roof, thereby allowing more than 4 collectors per group. In all cases, it is essential to ensure that complete drainage of all collectors occurs; so the banks should be mounted at a slight angle, and all pipework must drain back to the tank.

In snowy weather, our system can detect collectors snowed up overnight and pre-heat them to shed the snow, thereby gaining many morning hours of solar collection that other systems (like solar vacuum tube designs) often struggle to because of their shape and inability to self-heat.

For a given roof area, the net aperture area of a flat plate collector is much larger than the net aperture area of a vacuum tube collector.

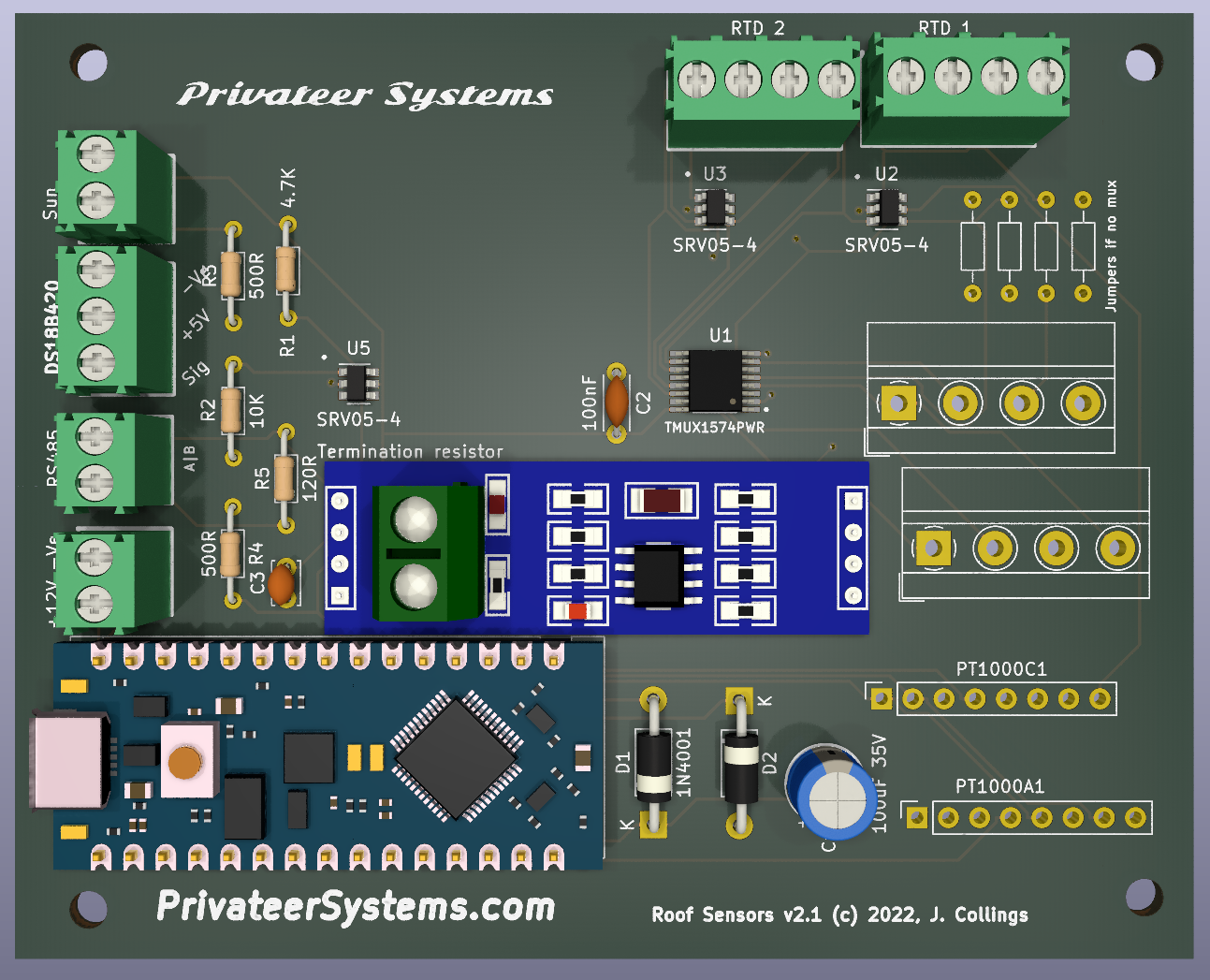

Remote temperature sensor

Each group of banks of solar collectors needs temperature monitoring. We do this with our custom sensor module which reads data from a platinum sensor mounted in a small well in the final collector of the bank. The module can also detect daylight and ambient temperature. These rooftop modules are typically the last nodes in the RS485 network so they run through a lightning suppressor. In this way, rooftop data is safely transmitted to our master control unit.

Each group of banks of solar collectors needs temperature monitoring. We do this with our custom sensor module which reads data from a platinum sensor mounted in a small well in the final collector of the bank. The module can also detect daylight and ambient temperature. These rooftop modules are typically the last nodes in the RS485 network so they run through a lightning suppressor. In this way, rooftop data is safely transmitted to our master control unit.

Tanks

At the moment we are using standard IBC containers which work well as the systems is non-pressurised. Each container is a cubic metre. They are easily insulated. Evaporation is minimal and the medium is plain water: we measured about 100cc evaporation per day from our 1,000 litre test system.

IBCs are available worldwide and can be re-purposed.

Logging

We have a logging daemon for Windows or Linux. (We run it on a Raspberry Pi.) It collects data from the RS485 network, processes it, and then writes it to a CSV file which it can then upload to a FTP server continuously.

We also have a small Javascript HTML file that displays a performance graph to a user derived from this CSV data.

Connectivity

The system requires mains power. The modules needed for a single array use about 0.5W at 12VDC and the pump up to 70W at full flow (where it will be scavenging several kW of heat from the panels).

There is no need for any internet connection, unless you want to upload logging information to an ftp server.

The autonomous nature of the system was designed in from the start for security and reliability. If something is connected to the internet, it is inherently and intrinsically vulnerable one way or another.

Disclaimer:

Errors and omissions excepted. No reliance can be made upon the accuracy of the information contained herein, and no liability arising from the information and/or the use of the devices is accepted. These devices are prototypes only and not for sale.

E. & O. E.